Argent can produce custom gasketing and sealing solutions for the automotive industry and beyond. Our die cutting and other converting capabilities help deliver proven, effective and economical solutions for a wide variety of applications. All of our unique materials and composites can be custom converted to meet the exacting needs of your specific gasket or sealing application.

Gasketing & Sealing Applications

Argent can create custom gasketing and sealing solutions for a range of applications, including:

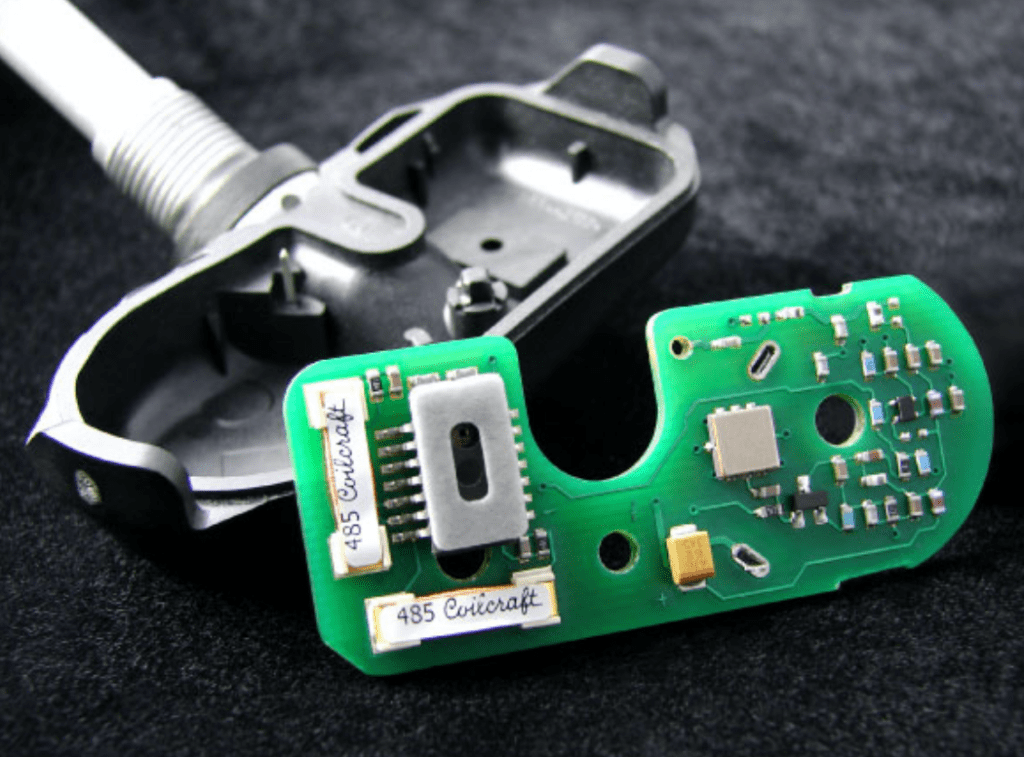

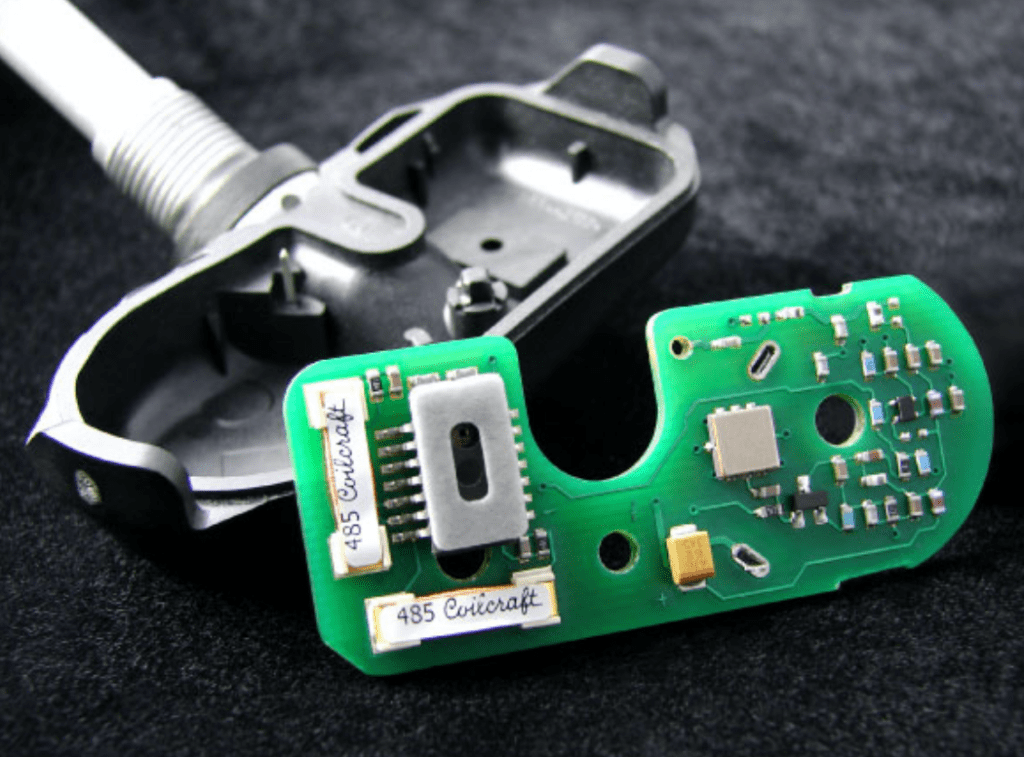

- Ingress protection

- Reducing BSR/NVH

- Gap filling for HVAC systems

- Fuel system sealing

- Sealing door and roof panels

The Argent Gasketing and sealing solutions Value

We can manufacture a wide range of gasket sizes with tight tolerances using our advanced die cutting capabilities. We match our process to meet each customer’s unique needs and can assist with materials selection to ensure excellent performance and durability.

- Always tested against OEM specifications

- Industry-leading gasketing technology

- Prototyping available with short lead times

Gasketing and Sealing Materials

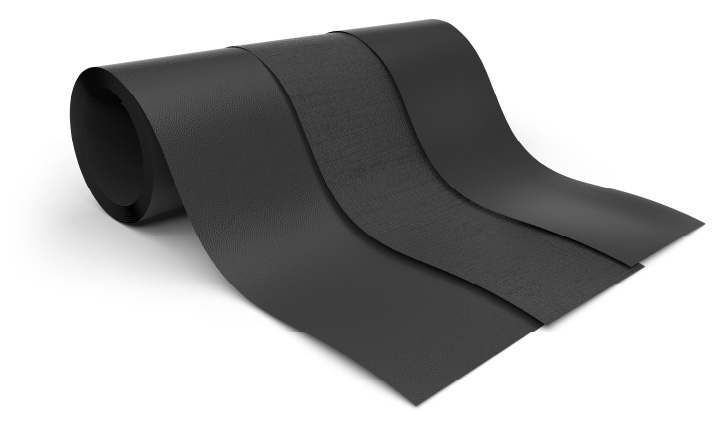

Rubber

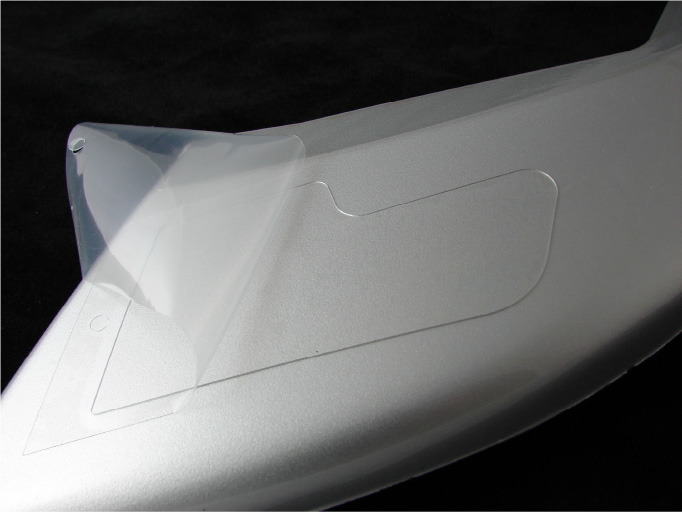

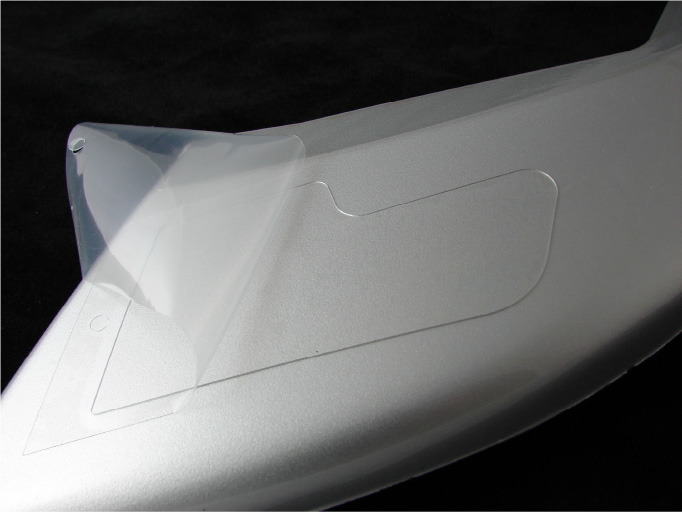

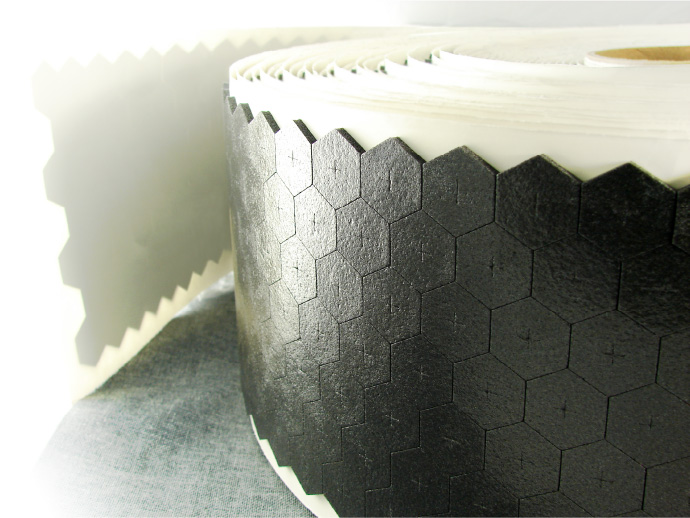

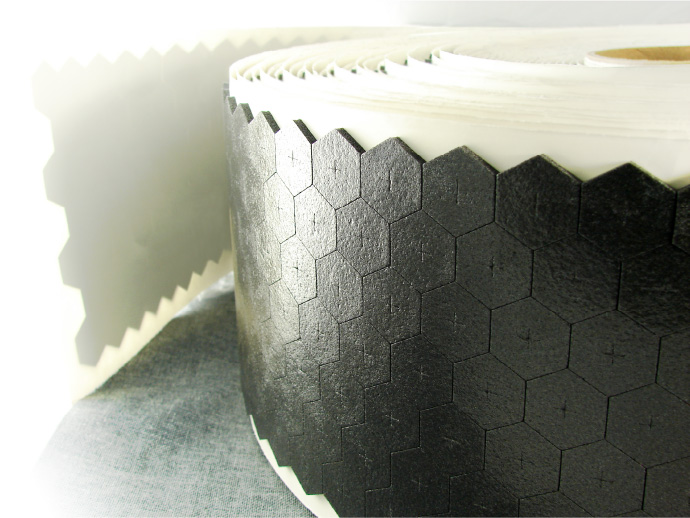

Self-adhesive Foam

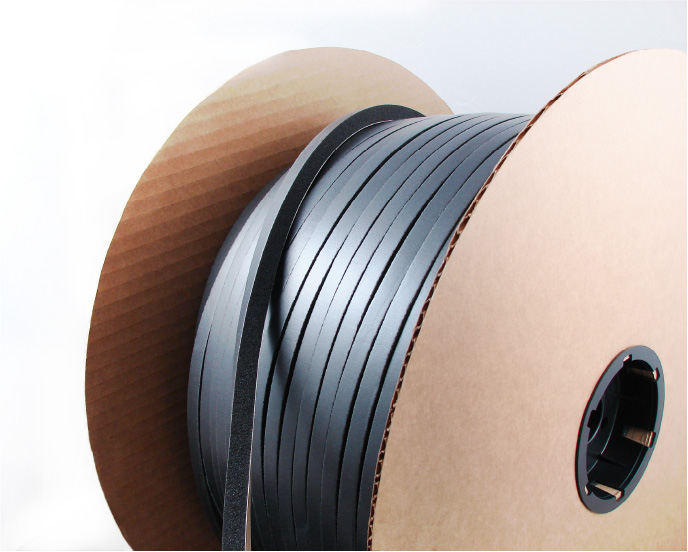

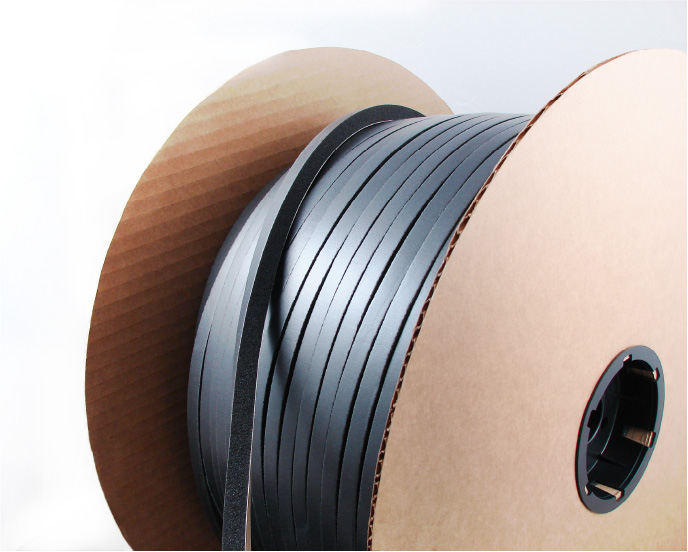

Plainbacked Foam

Like the self-adhesive variety, plainbacked foam is typically used to seal gaps and prevent the intrusion of dust, water and air. When attachment is not a concern due to mechanical retention or other means, plainbacked foam provides a variety of gasketing and sealing options.

A large number of product types are available, but PVC, neoprene blend, polyethylene and polyester/urethane are used most commonly.

Double-Coated Foam Tape