40 Years of Expertise

Lamination

Rapid Prototyping

Precision Die-Cutting

- Anti-Shatter, Anti-slip, Anti-Squeak Products

- Bonding, Attaching, Fastening

- BSR / NVH, Acoustical Insulation, Wind Noise & Sound Dampening

- Gasketing, Masking, Cushioning, Protecting & Sealing

- Medical, Surgical, Diagnostic Products

- Electronic shielding & conductive components

- Spacers, Shims & Washers

Laser Cutting

- Greater part design freedom & more intricate shapes

- Narrower wall thicknesses

- Tighter tolerances & greater repeatability

- Can solve most attachment challenges

- Increased manufacturing process design flexibility

- Tool-free design changes

- Greater part-to-part spacing options

- Increased overall choices in method of part supply

In addition to allowing us to produce very small and intricate shapes, laser cutting can also sometimes be an effective option when lead times and cost of conventional tooling just doesn’t make sense.

Flex Cutting

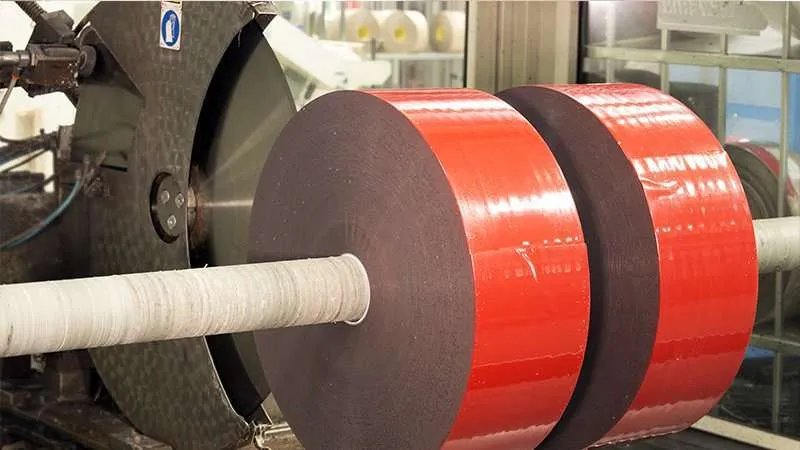

Slitting

Argent can slit rolls of material in a variety of disciplines, including Lathe Slit Rolls & Rewind Slit Rolls. Materials can be efficiently and accurately lathe-slit due to precise microprocessor control over blade and mandrel movement. Lathe-slit rolls are available in a variety of standard and custom lengths, widths, and diameters.

Rewind slitting offers several product features, high capability at very narrow widths, and allows for core/ reel substitution and changes to roll length/diameter. Rewind-slit rolls are also available in a variety of standard and custom lengths, widths, and diameters.

Sewing

Printing

Assembly & Finishing

Product Delivery Systems

The term, delivery system, describes the method of supply of a specialty-cut product. Maximize assembly efficiency, repeatability, and return on piece price by selecting the delivery system best suited for your application and assembly process.

Individual Pieces

Individual pieces are parts supplied as separate entities, and usually bulk-packed. Components typically supplied as individual pieces are those that are either: larger, lower volume, or hand assembled, due in part to their relatively low piece price and tooling costs.

Generally Recommended for:

Hand Assembly

Roll Form

When supplied on rolls, parts are delivered via a continuous release liner wound around a core. Products typically supplied on rolls are smaller, less than two feet wide by two feet long, and typically much smaller.

Best suited for higher volume parts, this highly economical method of supply provides an efficient delivery mechanism by facilitating automation or simply expediting hand assembly. Manufacturing parts on rolls also provides additional consumer benefits; parts may be supplied with nearly any feature.

Generally Recommended for:

Hand Assembly

Fixtured or Other Assembly

Automated Assembly

Sheet & Pad Form

Supplied on sheets, a pre-determined number of self-adhesive parts are delivered via a release liner of fixed length and width. Products typically supplied on sheets are those that might be used together, as in a kit, or those which cannot be wound around a core.

This versatile and economical method of supply also provides efficient part delivery by facilitating sheet-fed automation or simply expediting hand assembly. Manufacturing parts on sheets provide additional consumer benefit; parts may be supplied with nearly any feature. Matching pad quantity to application needs can simplify assembly.

Generally Recommended for:

Hand Assembly

Fixtured or Other Assembly

Automated Assembly